Plc Tutorial,Online Plc Tutorial,Plc tutor,Plc Tutorials - This blog contains complete details of PLC Need Live PLC Training logon to: http://tiia.co.in/

Saturday, July 16, 2011

Comparison Instructions

Bit Logic Instructions

Friday, May 27, 2011

Procedure for Configuring SIEMENS

Basic Procedure

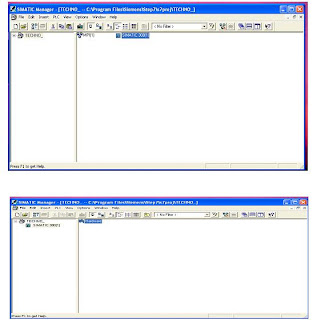

To configure and assign parameters to a structure, proceed as shown below:

Creating a New Project

- Select the project in the left half of the project window.

- Select the menu command Insert > Station > SIMATIC 300-

The station is created with a preset name. You can replace the name of the station with a more relevant name of your own.

Configure the Hardware

Rack

The rack appears in the form of a small configuration table in the upper part of the station window. In the lower part of the window, the detailed view of the rack appears with additional information such as the order number, MPI address, and I/O addresses.

Alternatively to steps 1 and 2, you can also double-click the rack in the

- Slot 1: Power supply only (for example, 6ES7 307-...) or empty

- Slot 2: CPU only (for example, 6ES7 314-...)

- Slot 3: Interface module (for example, 6ES7 360-.../361-...) or empty

- Slots 4 through 11: Signal or function modules, communications processors, or free.

Save and Compile

Project Structure

- Configuration data on the hardware structure and parameters for modules,

- Configuration data for communication in networks, and

- Programs for programmable modules.

Project Object

Station Object

Programmable Module Object

S7 Program Object

Source File Folder Object

Block Folder Object

SIEMENS - Tutorial

SIEMENS ADDRESS

System Default Address Input I124.0 I124.7

Output Q124.0 Q124.7

User Define Address Input I0.0 I0.7

I1.0 I1.7

Output Q0.0 Q0.7

Q1.0 Q1.7

Internal Memory Bit M0.0 M0.7

M1.0 M1.7

Upto M124.0 M124.7

Integer MW0 , MW2 , MW4 , Upto MW124

Double Integer MD0 , MD4 , MD8 , Upto MD124

Timer T0 Upto T255

Counter C0 Upto C255

Tuesday, April 26, 2011

PLC Wiring

The standard wire gages are listed below:

Monday, April 18, 2011

ALLEN BRADLEY PROGRAMING GUIDE

Then select CPU model

PLC SCAN PROCESS

PLC PROGRAM SCAN

Saturday, April 16, 2011

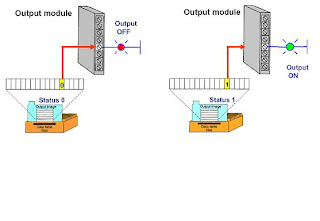

PLC OUTPUT TABLE FILE OPERATION

Processor continually activates or deactivates ouput status according to output image table file status

PLC INPUT TABLE FILE OPERATION:

Processor continually reads current input status and updates input image table file.

INPUT TABLE FILE OPERATION:

PLC PROCESSOR MEMORY ORGANIZATION

The memory of a PLC is organized by types.

The memory space can be divided into two broad categories:

Program and Data Memory:

Advanced ladder logic functins allow controllers to perform calculatins, make decisions and do other complex tasks. Timers and counters are examples of ladder logic functions. They are more comples than basic inputs contacts and output coils and relay heavily upon data stored in the memory of the PLC.

The user program will account for most of the memory of a PLC system.

Program files contain the logic controlling machine operation.

This logic consistes of instructions that are programmed in a ladder logic format.

DATA FILES:

The data file protion of memory stores input and output status, processor status, the status of various bits and numerical data.

What is a PLC?

PLC is a device, which is used to control a machine or process as per the human control sequence. A PLC monitors inputs, makes decisions based on its program, and controls outputs to automate a process or machine.

Advantages

• Smaller physical size than hard-wire solutions

• Easier and faster to make changes

• PLCs have integrated diagnostics and override functions

• Diagnostics are centrally available

• Applications can be immediately documented

• Applications can be duplicated faster and less expensively

PLC HARDWIRED CONTROL

Prior to PLCs, many of these control tasks were solved with contactor or relay controls. This is often referred to as hard-wired control. Circuit diagrams had to be designed, electrical components specified and installed, and wiring lists created. Electricians would then wire the components necessary to perform a specific task. If an error was made the wires had to be reconnected correctly. A change in function or system expansion required extensive component changes and rewiring.

DRAWBACKS:

Bulky and complex wiring.

Difficult to change the logic.

Unreliable.

RELAY :

RELAY LOGIC – AND GATE:

Logic gates and Electronic Circuits are used

Ease of programming

Ease of maintenance

Drawbacks:

Difficult to Troubleshoot while Change the Logic of the Process

Difficult to expand

Not suitable for industrial conditions